Catalogue: https://www.hyooauto.com/static/upload/HY-CNC416.pdf

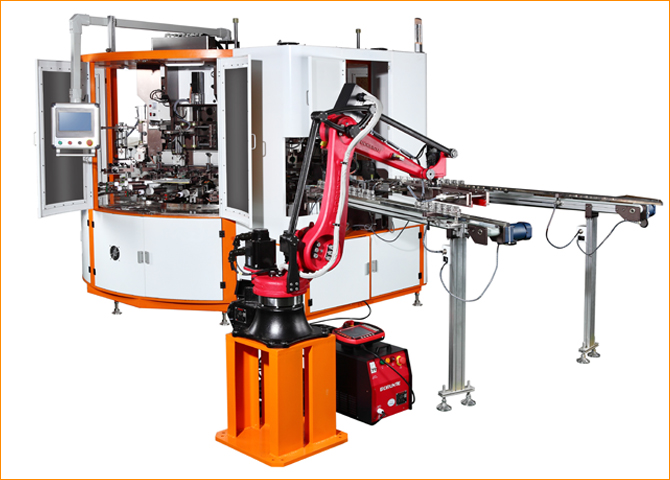

Typical Features of Four Colors Automatic Servo Screen Printing and UV Curing Production Line HY-CNC416

· Suitable for surface screen printing of various shapes’ bottles such as cylinder, square, oval, triangle, etc.(cosmetics, wine bottles, beverage bottles, and general-purpose containers); suitable for UV and solvent ink printing

· Adopt high-precision index, full servo drive system, fast printing speed, stable and reliable quality, convenient and quick debugging, and wider applicability

· 10 inch WEINVIEW touch screen (network type)

· Japan OMRON motion controller

· The turntable is driven by a 12-part Dex index

· The second axis of the printing mechanism is OMRON servo motor with ball screw, a total of 4 groups

· The 16-axis tube holder is controlled and operated by OMRON absolute servo motor

· The main drive is controlled by Italian SITI reducer with motor and OMRON inverter

· The product loading and unloading mechanism is driven by 2 sets of OMRON servo motors to run more smoothly and accurately

· The ball screw and guide rail adopt international famous brands, which have higher precision and longer life.

· The use of LED electronic UV system (energy saving and environmental protection) is more reasonable, and the operation of employees is easier and safer

· UV curing is also servo-driven, and the curing time can be set arbitrarily according to the requirements of product printing, which greatly increases the adhesion of the ink

· It has an independent vacuum system, and the anti-wear products can be manufactured by vacuum suction, which greatly prevents wear during the production process, and ensures that the independent vacuum makes the printing quality more stable.

· It can print triangles, squares, ellipses and other polygons in the same color at one time

· The flame treatment adopts servo drive, which can realize the arbitrary adjustment of the speed

· It uses laser sensor or CCD vision to detect the bottle mouth or pattern positioning point to realize multi-color overprinting and precise control of patterns based on the position of the product surface

· It is easy to change and debug, without gears, so as to avoid inaccurate color registration after the gear and rack wear, and greatly save the adjustment time

· It uses 16 stations, which greatly reduces the cost input after the change, so as to save the corresponding cost for the customer

· CCD post-print inspection system can also be configured, and space reserved for future additions

· Robot Hand Discharging Mechanical Arm can be customized

· The main structure design is more reasonable, and it has made major optimizations than the existing domestic machines, and can achieve stable and efficient production

Website: www.hyooauto.com

Skype/Email: sales@hyooauto.com

Dongguan Huayu Automation Technology Co., Ltd.

Own Brands: Huayu Automation(logo HYOO), ONCE Machinery(logo ONCE)

Chinese Professional Manufacturer of Automatic Screen Printing Machines

Add.: A Building, 168# Changheng Road, Changping Town, Dongguan City, Guangdong Province, China 523562