Populuar Automatic Servo Screen Printing Machine:

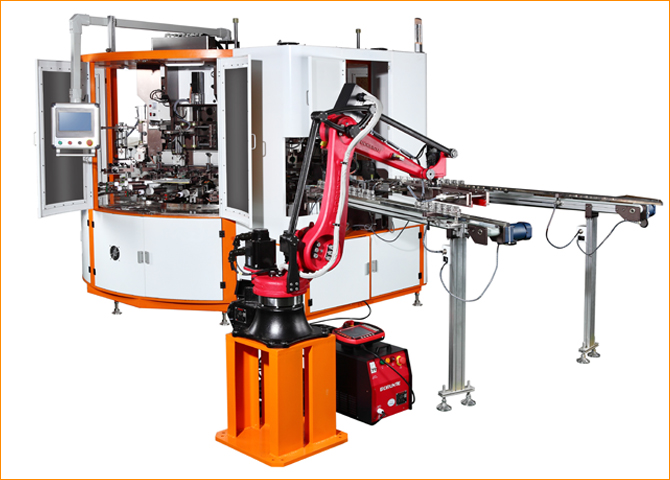

HY-CNC106: Automatic Servo Single Color Screen Printing And UV Curing Production Line

HY-CNC416: Four Colors Automatic Servo Screen Printing And UV Curing Production Line

Will the precision of the servo screen printing machine be higher than that of the traditional screen printing machine? Is it necessary to spend more price to buy a servo screen printing machine?

Maybe many people don’t know what a servo screen printing machine is. In fact, the servo screen printing machine is named after the servo motor in the power system. Compared with the servo motor, the performance of the stepping motor used in the traditional screen printing machine is not as high as that of the servo motor.

The precision of the servo screen printing machine is higher than that of the traditional screen printing machine. Let’s take a look at the working principle of the screen printing machine for the specific reasons! The working principle of the screen printing machine is driven by the stepping motor of the traditional screen printing machine. The voltage of 220V or industrial 380V is used to drive the printing work, which is relatively stable, but it is not as good as the servo motor. The servo screen printing machine is currently more high-end in the industry, the printing of servo motor screen printing machines are very precise, generally applicable to the fine printing industry, the advantage of servo screen printing machines is that they can freely control the printing position of up, down, left and right, automatically return to the origin and many other step screen printing machine can’t achieve the effect.

Servo screen printing machines are superior to traditional stepping motors in speed and load capacity. Due to the high stability of servo motors, the printing accuracy will naturally be relatively high. Moreover, the debugging of the servo screen printing machine is much more convenient than that of the traditional screen printing machine.